Marya Dust Free High Cleanliness Level 1000 Class Clean Room Laboratories for Animal Lab Industry

Basic Info.

| Usage | Warehouse, Villa, Dormitories, Temporary Offices, Workshop |

| Certification | ISO, CE, SGS |

| Customized | Customized |

| Transport Package | Standard Export Package |

| Specification | Standard/Customized |

| Trademark | Marya |

| Origin | China |

| Production Capacity | 10000PCS/Month |

Packaging & Delivery

Package Size 100.00cm * 100.00cm * 100.00cm Package Gross Weight 50.000kgProduct Description

Marya Dust Free High Cleanliness Level 1000 Class Clean Room Laboratories for Animal Lab Industry

Product Description

Different levels of experimental animals have different requirements on the design and management of animal laboratory cleanrooms.Sterile, known bacteria and animals without special pathogens need to be kept in a sterile or aseptic environment as much as possible. This environment is currently called a barrier environment in the world, that is, a barrier is used to separate animals from the surrounding polluted environment.

From the perspective of controlling microorganisms, this environment is divided into five categories: isolation system, barrier system, semi-barrier system, open system and laminar flow rack system.A. Isolation system: It is a system for keeping animals in containers with operating gloves, and is used for keeping sterile animals and living animals. The interior maintains the 100-level cleanliness required by microorganisms, but the rooms and operators do not need to be considered as sterile rooms.B. Barrier system: The aseptic clean room of about 10,000 to 100,000 grades is used as a breeding room, which is mainly used for long-term feeding and breeding of animals without special pathogens. Strict management is implemented for entering the room, such as showering, changing underwear, etc.C. Semi-barrier system: relax the management of people and objects entering and leaving the room in the barrier system, and the composition is roughly the same as that of the barrier system.D. Laminar flow rack system: the cage is placed in clean horizontal laminar air. Commonly used in small-scale breeding, but there is a risk of contamination when feeding, operating and handling in general rooms. Can be used as a half-barrier supplement.E. An open system is a system that does not decontaminate the entry and exit of people, objects, air, etc., but usually requires a certain degree of cleaning managementCharacteristic:1. The walls and floors are clean and seamless, the treads have no flanges, and form a plane with the walls. The corners are rounded, and the ground is guaranteed to have sufficient strength.2. Doors and windows should be opened in a direction that is suitable for indoor ventilation. There should be sealing strips on the edge of the door, and a device to prevent wild rats from entering the door; windows in clean animal rooms should be sealed.3. If 12 hours of lighting in the light and shade or natural light meets the requirements, the light needs to illuminate the whole house. The lighting is set on the porch for easy control. The illuminance is required to be around 1000lx.4. The cleanliness of the clean animal room is 100,000, the ventilation requirement is 8~15 times/h, the room maintains a positive pressure of 5~10Pa, and the new ventilation and direct current air conditioning system.

Technical Parameters:

| Effective width | Wall panel: 950mm 1150mmCeiling panel: 950mm |

| Length | According to customer's request(less than 7500mm) |

| Core Materials | PU/Rock Wool/Glass Magnesium |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: PU/Rock Wool/Glass Magnesium | |

| Thickness | Color steel sheet: 0.3-0.8mmRock wool: 50mm 75mm 100mm |

| The Density of Rock Wool | 40kg/m3 -120kg/m3 |

| Color | RAL Standard |

| Character | Fireproof, heat insulation, sound proof, green and environmental friendly |

| Use | pharmaceutical & electronic clean rooms, hospital operating rooms, food processing factories, offices, etc. |

About Us

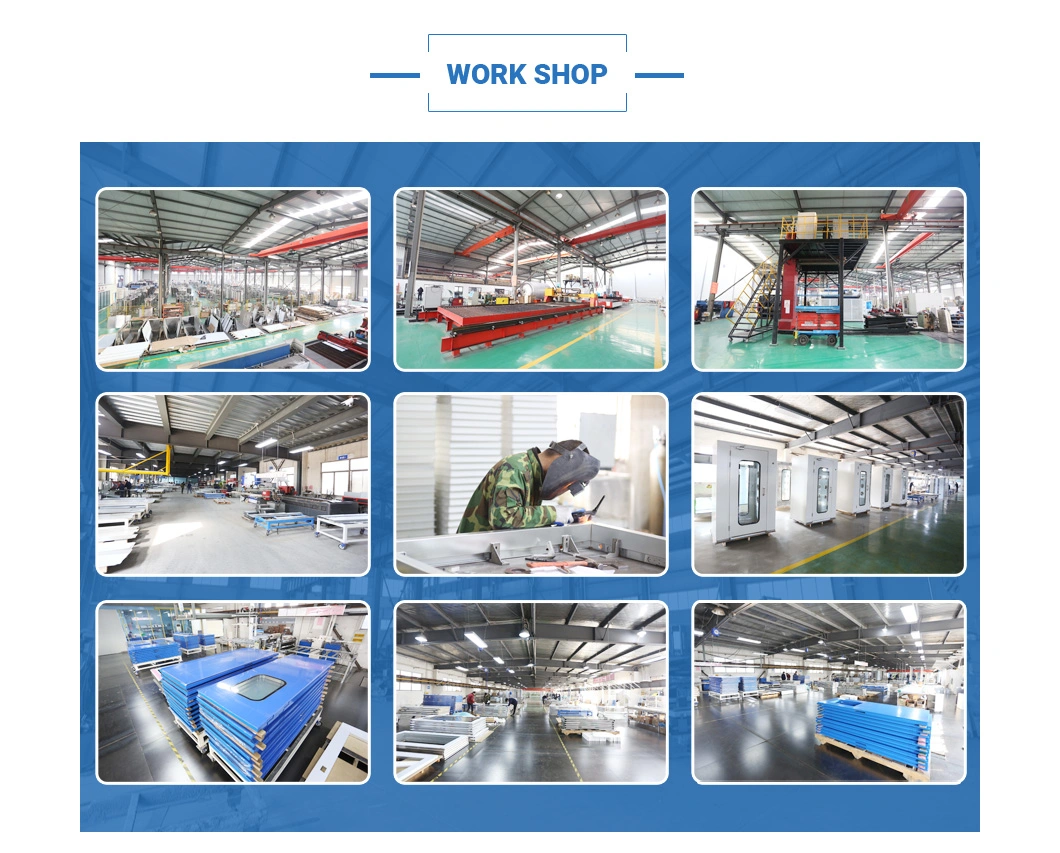

Workshop

Certificate

Project case

Our Customer

Exhibition & Our Team

Packaging & Shipping